# Denox/Desox Technologies: Innovations in Emission Control

## Introduction to Denox/Desox Technologies

Denox and Desox technologies represent cutting-edge solutions in the field of emission control, specifically targeting nitrogen oxides (NOx) and sulfur oxides (SOx). These pollutants are major contributors to air pollution, acid rain, and respiratory problems in humans. As environmental regulations become increasingly stringent worldwide, industries are turning to advanced technologies like Denox and Desox to meet compliance standards while maintaining operational efficiency.

## The Science Behind Denox Technology

Denox (De-NOx) technology focuses on the reduction of nitrogen oxides from industrial exhaust streams. The most common methods include:

– Selective Catalytic Reduction (SCR)

– Selective Non-Catalytic Reduction (SNCR)

– Low-NOx burners

– Exhaust Gas Recirculation (EGR)

SCR systems, the most widely used Denox technology, employ a catalyst and a reducing agent (typically ammonia or urea) to convert NOx into nitrogen and water vapor. This process can achieve reduction efficiencies of up to 90%, making it highly effective for power plants, marine engines, and industrial boilers.

## Desox Technology: Tackling Sulfur Emissions

Desox (De-SOx) technologies specialize in removing sulfur oxides from flue gases. The primary methods include:

– Wet scrubbing (flue gas desulfurization)

– Dry scrubbing

– Spray drying

– Sorbent injection

Wet flue gas desulfurization (FGD) systems are the most common, using alkaline slurries (typically limestone or lime) to react with SO2 and produce gypsum as a byproduct. Modern FGD systems can remove up to 99% of sulfur dioxide from exhaust streams.

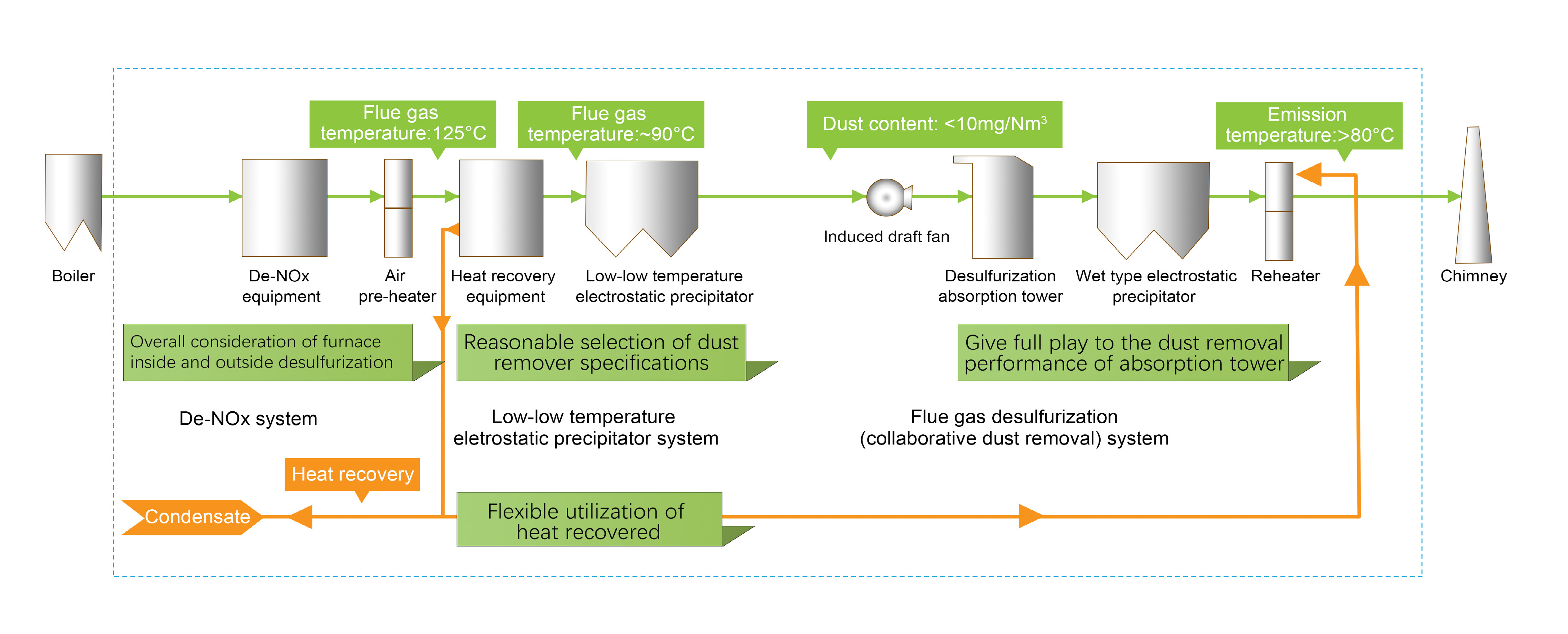

## Combined Denox/Desox Systems

Many industrial facilities now implement integrated Denox/Desox systems to address both NOx and SOx emissions simultaneously. These combined systems offer several advantages:

– Reduced footprint compared to separate systems

– Lower capital and operational costs

– Improved overall emission control efficiency

– Simplified maintenance procedures

Hybrid systems often combine SCR for NOx reduction with wet FGD for SOx removal, creating a comprehensive solution for clean air compliance.

## Emerging Innovations in Emission Control

The field of Denox/Desox technologies continues to evolve with new advancements:

– Novel catalyst materials with higher activity and longer lifespan

– Advanced control systems using AI for optimal reagent dosing

– Modular, compact designs for easier retrofitting

– Integration with carbon capture technologies

– Development of zero-emission combustion technologies

These innovations are helping industries meet increasingly strict environmental regulations while improving energy efficiency and reducing operational costs.

## Environmental and Economic Benefits

The widespread adoption of Denox/Desox technologies has led to significant environmental improvements:

– Dramatic reductions in acid rain formation

Keyword: denox/desox technologies

– Improved air quality in industrial regions

– Protection of ecosystems from nitrogen and sulfur deposition

– Compliance with international environmental agreements

From an economic perspective, these technologies help industries:

– Avoid costly regulatory penalties

– Create marketable byproducts (e.g., gypsum from FGD systems)

– Improve public perception and corporate responsibility

– Future-proof operations against tightening regulations

## Conclusion

Denox and Desox technologies have become essential tools in the global effort to reduce industrial emissions and combat air pollution. As these technologies continue to advance, they offer industries practical solutions for environmental compliance while maintaining economic viability. The ongoing development of more efficient, cost-effective systems ensures that Denox/Desox technologies will remain at the forefront of emission control strategies for years to come.